Theakston Brewery and Ellers Farm Distillery combine skills to create a new world whisky in the heart of North Yorkshire

We were approached by Ellers Farm Distillery shortly after the establishment of their new distillery business in Buttercrambe near Malton in North Yorkshire. With ambitious plans for national and international scale production capacity, Ellers Farm wished to develop a high quality Yorkshire whisky to take advantage of the fast-growing English whisky market.

To create a malt whisky a distiller will first need the creation of a distillers wash i.e. beer brewed without hops and then fermented. To create a very special Yorkshire malt whisky, Ellers Farm needed to go no further than T&R Theakston, the famous Masham brewers who have need brewing beer for

nearly two centuries standing.

Brewed using Yorkshire grown barley, malted in Castleford and brewed at the Theakston brewery in Masham, the wash is then shipped to Ellers Farm where it is then distilled by their team of expert distillers. Combining the skills of the world-renowned distiller Jamie Baggott with our brewing heritage we are making a malt whisky of unique character and quality, the perfect way to celebrate our proud Yorkshire credentials.

How It's Made

Milling

Our collaboration whisky journey starts in the barley fields of East Yorkshire, where pearl barley is harvested and then malted before being delivered to our brewery, where the ‘distiller’s wash’ for the whisky is ultimately created. Our mill, built by George Porteus, of Leeds at the beginning of the last century, crushes the barley into precisely the right sized grist.

Mashing

It is then mixed with our Well water in our cast iron Mash Tun, installed brand new in 1875. Here the starch is converted into glucose during the ‘mashing’ process. The ‘mash’ is gently sparged to ensure the correct gravity and amount of fermentable sugar prior to fermentation. Once complete the resultant liquid or ‘wort’ is ‘dropped’ into the copper.

Boiling

Our copper, installed second hand in 1933, works as perfectly now as it did the day it was installed. The wort is brought to the boil before being cooled prior to fermenting. The wort passes into the fermenting room where our unique twin-strain yeast takes three days to convert it into beer wash. The wort has now become ‘distiller’s wash’ and is delivered to Ellers Farm for the distillation process to begin under the expert guidance of Master Distiller, Jamie Baggot.

Distilling

Using their state-of-the-art distilling facility, Ellers farm can begin the column still distillation process. The ‘distiller's wash’ is fed into the column still at the top and begins descending, passing through a series of perforated plates. Simultaneously, hot steam rises from the bottom of the still, interacting with the wash as it flows downward, separating out the solids and unwanted substances, and pushing up the lighter alcohol vapours. This process is repeated numerous times until the desired character is formed and increasing the alcohol in the process.

Maturing

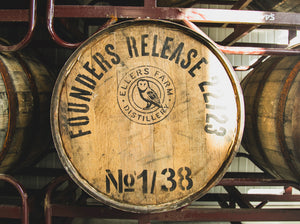

The maturation process takes place inside the 'one-fill' Bourbon oak casks, as is required for the development of the desired whisky characteristics which will take a minimum of 3 years. Only after those 3 years have passed can it be called a malt whisky.

Simon Theakston

"In the brewing industry, it is said that expertise comes with years of practice, but perfection takes a little longer. After nearly 200 years of brewing in Masham, we think we know what it takes to brew the perfect distillers wash for our partners, Ellers Farm Distillery. We are at the dawn of a most exciting journey to create a Yorkshire whisky of unimpeachable provenance, authenticity, and character."

Jamie Baggott - Master Distiller at Ellers Farm

"I have been distilling for over 15 years and have created numerous award-winning spirits, including Ballykeefe's first release single malt and traditional pot still Irish whiskies. I have taken all of my knowledge and experience and put it into the creation of our new whisky venture. What excites me the most about what we are doing today, compared to any that have come before, is that this is the perfect marriage of the very best production methods, honed over centuries by the Theakston family. There is no other collaboration like this."

Follow the journey from start to finish with the Evolution Collection

The Evolution Collection features five exclusive 50cl bottles of the New Make spirit, bottled at every stage of its flavour evolution. Our 0 Month New Make is already multi-award-winning, and collectors will be taken on an insider’s journey to experience how this unaged New Make spirit develops every six months, up to 24 months. There will only ever be 500 collections released, with no more once they’re gone.